Binding paper is one of our area’s of expertise at Graphic Image.

It goes hand-in-hand with printing, and booklets and newsletters are a popular choice for direct mailers.

What is Binding?

Stitches and coils and glue, oh my!

Simply put, binding is the act of attaching multiple sheets of paper together. There’s a vast array of options depending on the amount of sheets of paper, and what you’re hoping to achieve.

And not only that, but the type of booklet you’re printing is a factor as well.

There are many different binding types, and we’ve compiled a list of the most common ones.

1. Saddle-Stitching

Saddle-stitch binding is the most popular choice, and the most economical. Despite its name, this method is created with wire staples rather than stitching.

The name saddle-stitching comes from the sheets of paper draping over a saddle-like piece of machinery during the stapling process.

By nature, saddle-stitching needs to be done in multiples of 4. So, your booklet must be a minimum of 8 pages, with a suggested max of 64. Any higher than that, and the binding doesn’t normally perform as well as it could.

The projects for saddle-stitching are incredibly versatile. Brochures, newsletters, and magazines are just a few project examples.

- Cost-effective and the most inexpensive binding method.

- Fast turn-around time.

- Works great with low-page counts.

- Fits booklets with a range of different sizes.

- Used for both short and long production runs.

- Typically light-weight and great for mailing.

- Lies flat and stays open when reading.

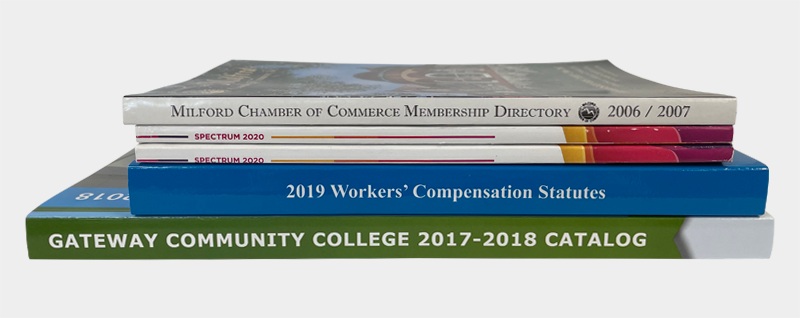

2. Perfect Binding

Another popular type, perfect binding is the process of attaching multiple sheets of paper with an adhesive. This results in clean and crisp edges.

Anything above 64 pages should be perfect-bound, versus anything less than 4mm in thickness should be saddle-stitched.

Soft-covered books are a popular use for this process. It’s a great alternative to binding for hardcover books, even though it’s less durable (and less expensive).

Additionally, perfect-bound books need to have a cover, which will wrap from front to spine to back.

The pages are gathered in order, and the edges are ground down to an irregular texture to better hold the adhesive. Then, the textured area is glued together, dried, and neatly trimmed. If you’re familiar, it’s the same concept as scratching clay in order to get two pieces of clay to stick together.

- Great alternative to saddle-stitching for project with more pages.

- Cheaper, yet less durable compared to binding for hardcover books.

- Looks professional with clean and crisp edges.

3. Spiral Binding

Also known as coil binding, this process is commonly used for things such as notebooks, guides, and handbooks. The coils for this process come in a wide array of colors, including metallic colors if you don’t want the plain, standard white.

The spiral coils are made from a high quality PVC plastic. This ensures sturdiness and durability when bound. The maximum size the coil spine can be is 2″. The spiral coils come in a variety of lengths. This means that they’re easily customizable to suit a wide range of projects.

A unique feature about spiral binding is that these booklets can open 360° which is excellent for note taking.

- Rotate pages by 360°.

- Lies flat and stays open while reading.

- Plastic coils come in a wide range of colors.

- Durable and sturdy.

- Good choice (and cost-effective) for short production runs.

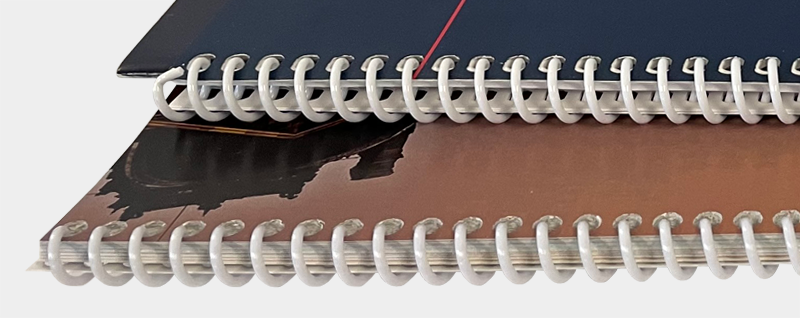

4. Wire-O Binding

Wire-O, also known as wire binding, is another process similar to plastic comb and spiral.

Like spiral, these booklets have the ability to rotate pages 360° without damaging the spine. This makes them a great option for notebooks, journals, and professional presentations.

However, compared to spiral binding, wire-O is less durable. Because wire-O uses metal wire, it’s more malleable than the PVC plastic used for the spiral process.

Similar to the plastic comb process, rectangular holes are punched through the booklet’s pages. Two small hoops of wire on a comb spine are looped through the holes.

The twin wire loops look clean and professional.

- Rotate pages by 360°.

- Lies flat and stays open while reading.

- Less durable than spiral’s PVC due to the coil material.

- High quality, clean, and professional-looking.

5. Glue-Spine Binding

Also known as folder glue binding. It’s a cross between saddle-stitch and perfect-binding, glue-spine looks just like saddle-stitch without the staples.

Gluing and folding the booklets are both done on the same machine. A huge upside to this type of process is that it doesn’t use staples compared to saddle-stitching. In short, this means saving money not having to use staples with the additional step.

College course catalogs and newsletters are some popular examples that feature this type of process.

- Similar cost to saddle-stitching.

- Large cost savings over saddle-stitching on runs over 20,000.

- Lightweight and great for direct mail.

- Unlike saddle-stitching, glued spines do not lie flat.

- Great for low-page counts.

- Limited to 8-12 and 16 pages on sheet-fed press. More page options on web press.

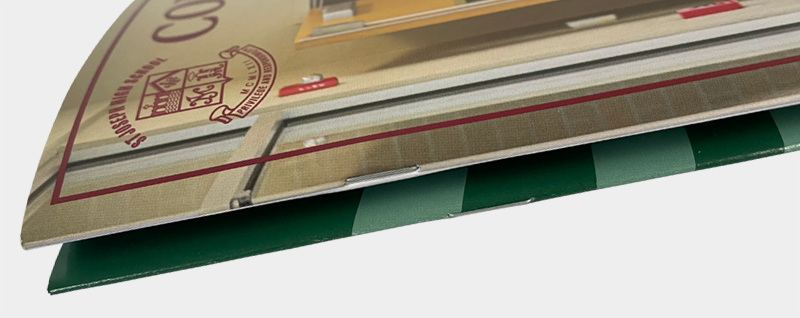

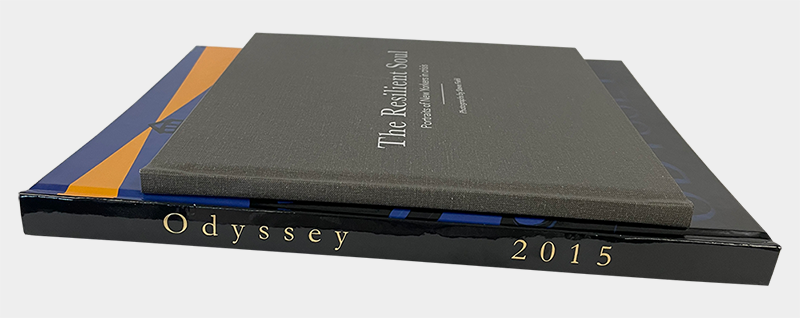

6. High-End Book Binding

Probably the most expensive on the list, this process binds hardcover books. Also known as hardcover or case binding, this is the best technique when durability is the main concern. Case-bound books can last decades or centuries.

All major books are hardbound, and this means the pages are sewn together in signatures. The signatures get glued to end-sheets which then get glued to the spine. However, the end-sheets are only used in books that have 60+ pages to ensure durability.

- High quality, sturdy, and durable.

- Professional and ornate-looking.

- Pages lie flat when the book is open.

- More expensive than simpler processes.

- Much heavier than other techniques.

7. Three-Ring Binding

Informational, cost-effective, and quick. The three-ring process is exactly as it sounds. Booklets or pages are hole-punched and inserted into a 3-ring binder.

- Fast and easy to assemble.

- Cost-effective.

- Pages lie flat and stay open when reading.

- Pages can be easily moved or replaced.

Conclusion

Given these points, there are tons of different binding processes out there, and we know how overwhelming it can be.

All in all, these 7 processes are among the most common, popular, and cost-effective.

Any one of them could be a great option for your next newsletter or booklet.

—

Interested in getting some printed booklets? You can email us at info@graphicimage.net or contact us here.